Home / News / Industry News / Are there any safety considerations when using Brushless DC motors?

Jul 24,2023

There are several safety considerations to keep in mind when using Brushless DC (BLDC) motors, especially in industrial, automotive, or consumer applications.BLDC motors are typically powered by direct current (DC) voltage, which can be hazardous. Ensure that appropriate electrical safety precautions are taken when working with BLDC motors, such as using proper insulation, grounding, and protection against electric shock.In some applications, BLDC motors may be driven by high voltages, especially in industrial or electric vehicle settings. Proper safety measures should be in place to prevent electrical hazards and protect personnel from accidental contact with high-voltage components.

BLDC motors can draw high currents during startup or under heavy loads. Protection circuits should be employed to prevent overcurrent situations, which could damage the motor or the driver. Additionally, thermal protection should be considered to prevent overheating and potential motor failure.

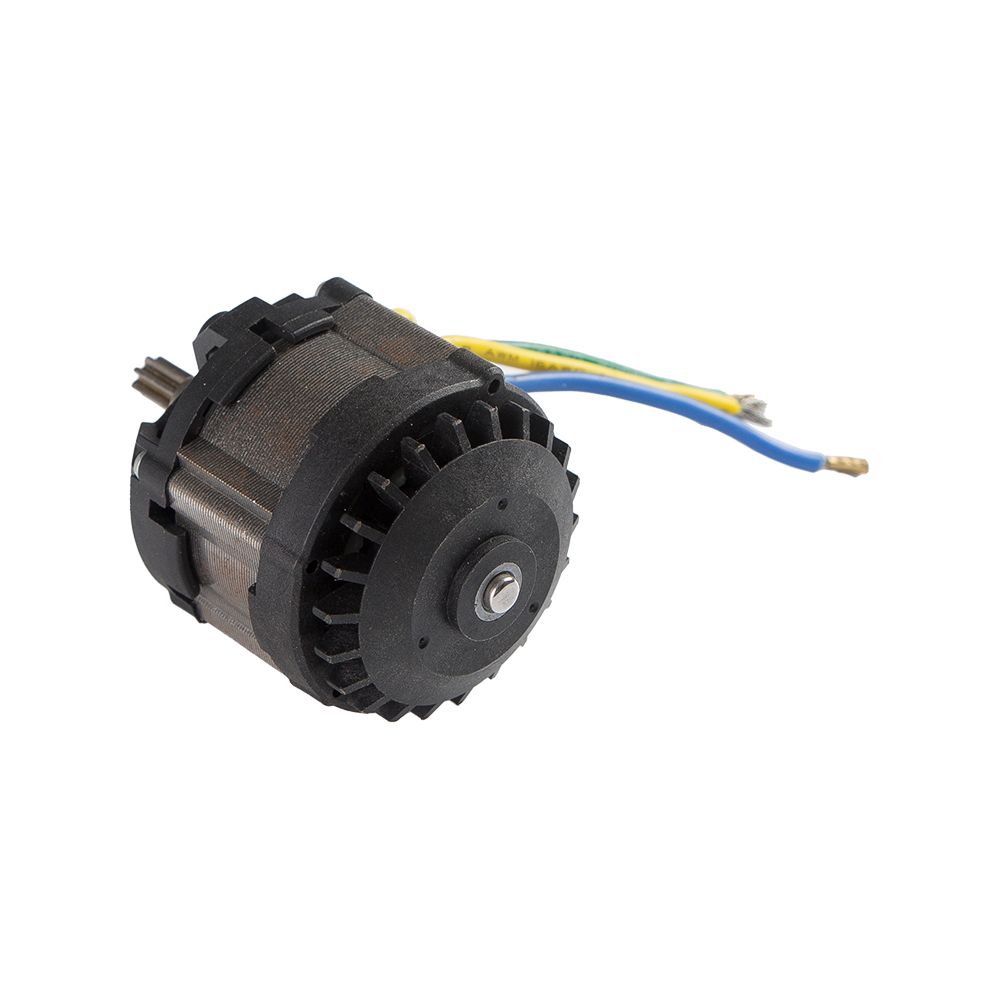

BLDC motors can generate electromagnetic interference (EMI) due to their switching nature. Proper shielding and filtering should be implemented to minimize interference with other electronic devices and ensure compliance with electromagnetic compatibility (EMC) regulations. BLDC motors may operate at high speeds and generate significant torque. Adequate guarding and protection should be in place to prevent accidental contact with moving parts, especially in applications like industrial machinery, Electric Power Tool Brushless Motors.

The control electronics and software used to drive BLDC motors should be designed with safety in mind. Robust control algorithms and fail-safe mechanisms can help prevent dangerous conditions, such as unexpected acceleration or loss of control.Proper grounding of the motor and associated electronics is crucial to prevent static buildup and reduce the risk of electrical hazards.Ensure that the BLDC motor and its control system meet relevant safety standards and certifications, such as CE, UL, or IEC standards, depending on the region and application.

Regular maintenance and inspection of BLDC motors are essential to identify potential issues early on and prevent safety hazards due to wear, aging, or malfunctions.

English

English 中文简体

中文简体 ++86 159 6738 9766

++86 159 6738 9766